Fuel cell systems have long been considered suitable for remote stationary power applications which suffer from a high cost of downtime, such as mobile base stations. Fuel cell design and manufacturing improvements, combined with increased volumes being produced, have seen costs decline, while technical performance, reliability and longevity have improved. Effectively as of now the cost of a fuel cell is about 10-15% more than an equivalent high end diesel generator normally used for the same purpose. If you also include items such as noise suppression or ATS for example, as required in telco deployments, the cost in terms of CapExp are closer. The big advantage of a Fuel Cell by comparison, is there is little maintenance needed (OpEx) so the total operating cost is much lower.

This has seen the technology transition over the last five years from field trials to commercial deployments, and is particularly prevalent in countries which already have good infrastructure, since this is a prerequisite for hydrogen distribution and delivery. For example, in the USA, Verizon current have several thousands of hydrogen gas powered Fuel Cell systems already deployed for several years now.

However, the markets and countries experiencing the largest growth, particularly in Telecom in base station deployments are in emerging markets, where hydrogen availability and poor road infrastructure make hydrogen compressed gas delivery difficult or costly. This, combined with an overloaded existing electrical grid and unpredictable outages, makes a compelling case for hydrogen production on-site.

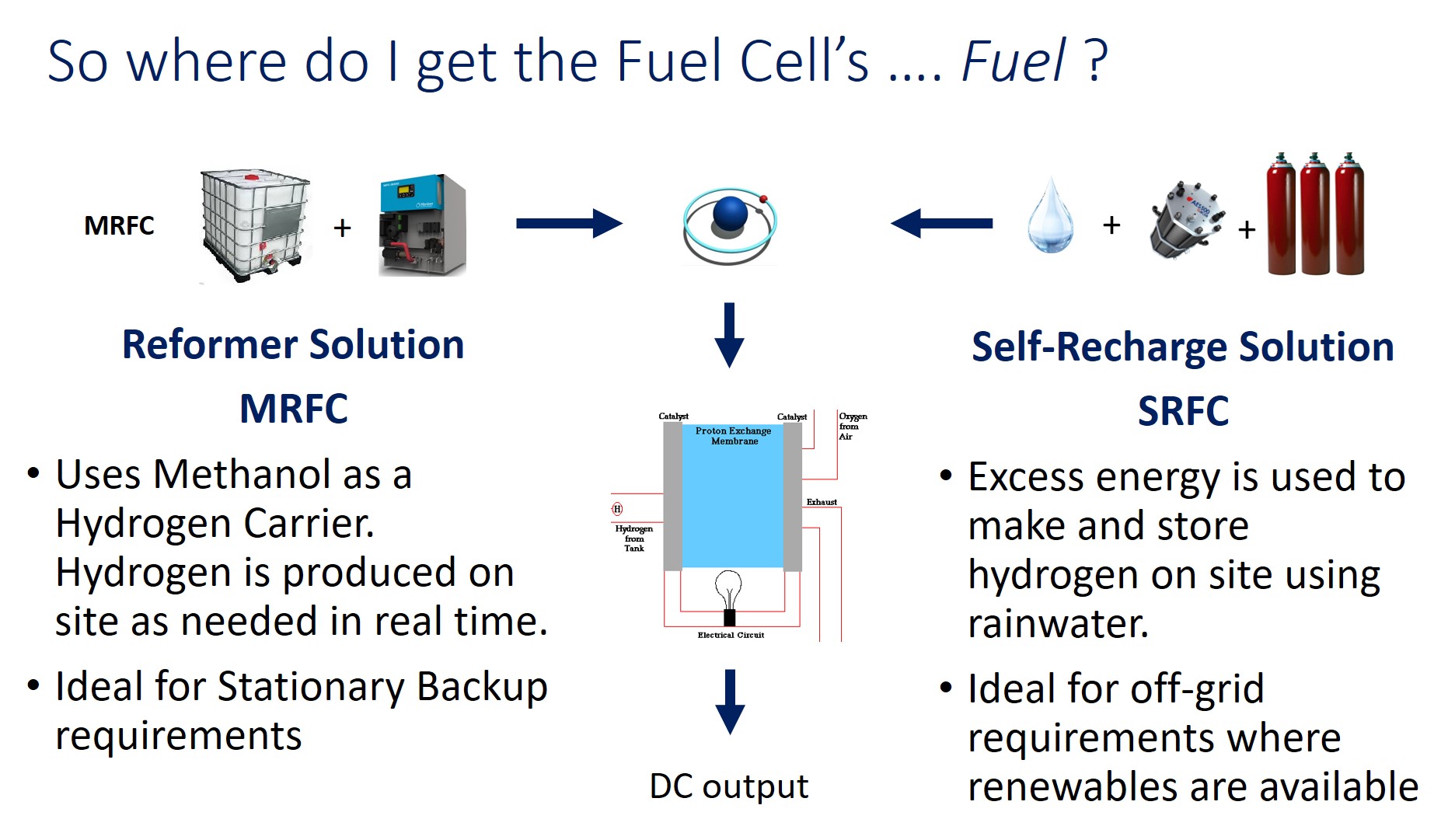

This can be done using a Reformer, which ‘reforms’ a liquid fuel to produce hydrogen on demand or by using an Electrolyser to ‘SRFC – Self Recharging Fuel Cell’ on site hydrogen vessels with hydrogen for use.